Casting Lead Down-rigger Balls in a Wooden Mold

Casting Lead Down-rigger Balls in a Wooden Mold

The finished product

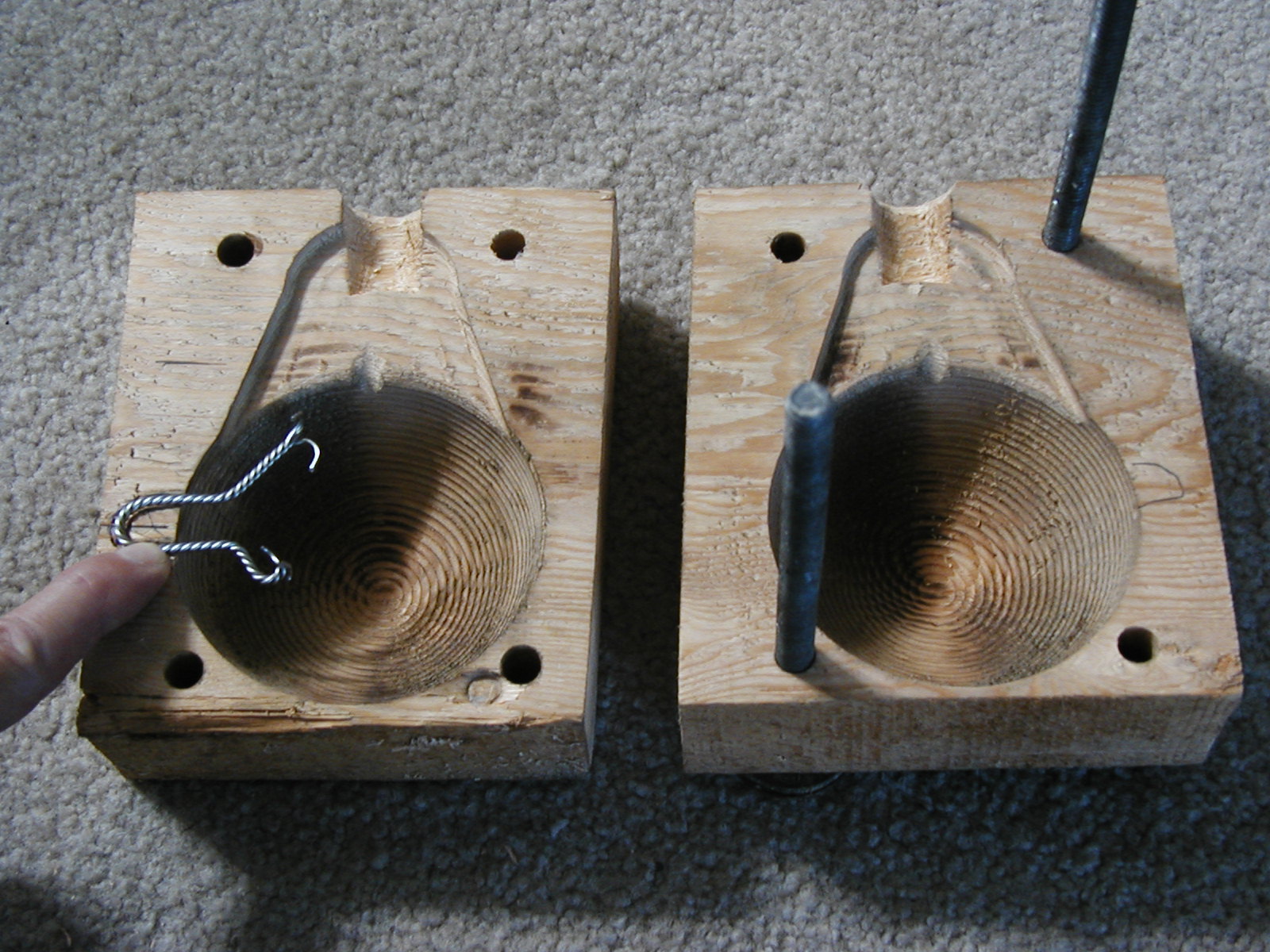

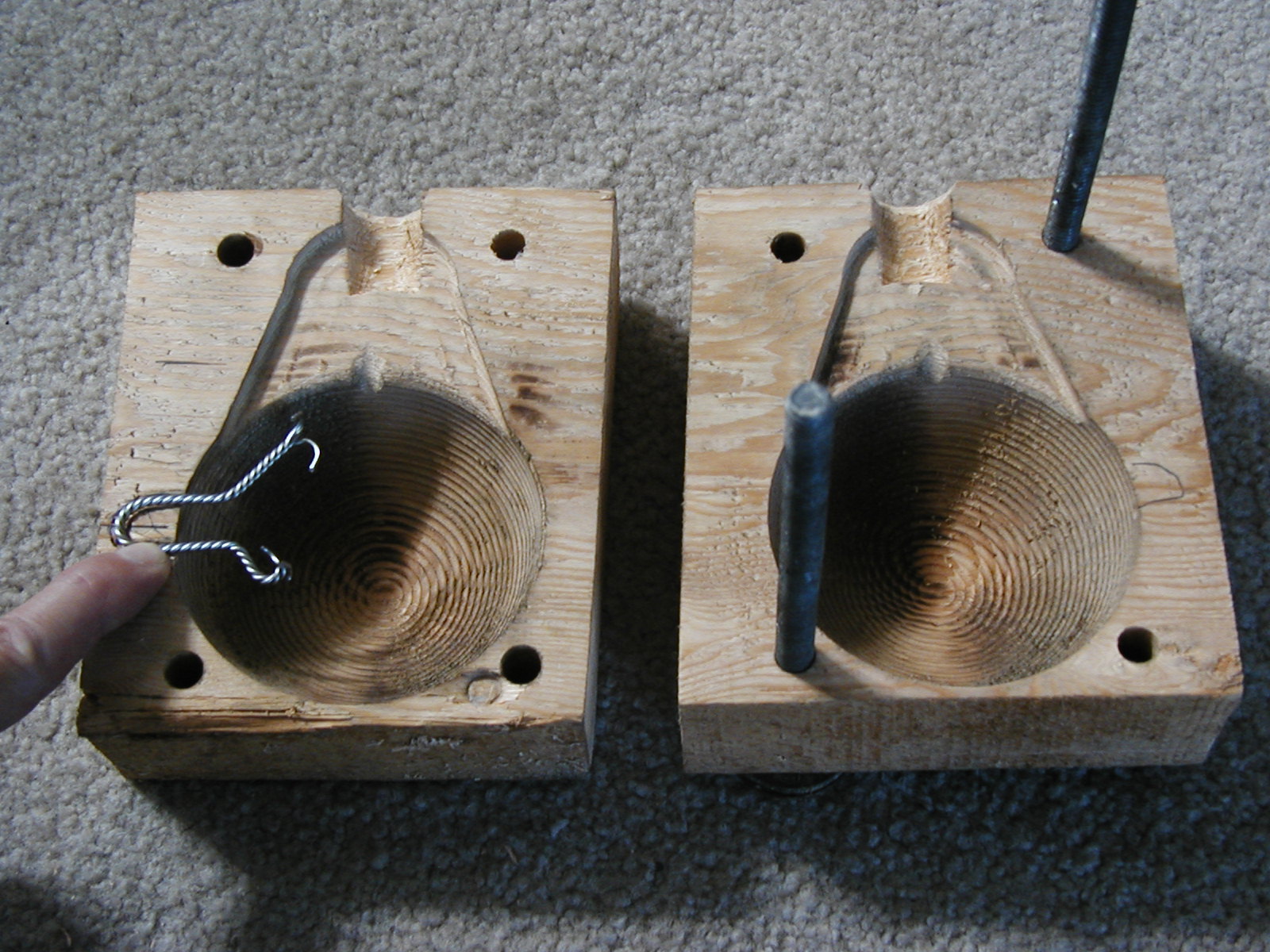

As Machined Fir Mold

Stainless Wire Loop, Bolts and Pouring Hole

Crispy Molds and 2 Rough Cast Balls

Project Description

This project was an experiment to see if lead down rigger balls could be cast using a cnc machined wooden mold.

The gcode is written such that some of the sizes can be easily adjusted to build different weights of balls and balls with or without fins.

The size I cast was supposed to weigh about 10lbs (4.5kg), but it came in about 10% lighter than expected.

The wood moulds smoke and burn when filled with lead and mine started to burn through after 2 balls were cast. If you keep the

walls of the mold a little thicker you may be able to get a little more service life from the mold. I just used a scrap piece if rough

fir 2x6 and the 10lb ball pattern just barely fit.

I used a 3/8" long endmill with radiused edges.... a true round nose bit will leave less of a pattern in the mold.

The scrap lead was melted with a tiger torch in a stainless steel cooking pot. I had lead left over from roof flashings and

some old SCUBA diving weights.

System Requirements

The gcode file supplied below was written for linuxcnc. The default mold size uses a block of fir

approximately 8"x6"x2" and your CNC will should have at least a similar working volume.

Electrical Drawing(s)

none

Source Code

The gcode file below uses named variables, looping and conditional constructs that are specific to the

linuxcnc machine controller package. The code does a roughing pass to hollow out the hemisphere, then a finishing pass

with finer resolution to clean up the hemisphere. The optional fin is then cut followed by the 4 bolt holes that hold

the 2 mold halfs together. The code cuts 1/2 of the mold. After the first half is cut, move over and rezero X and Y and

cut another hemisphere. I used the milling cutter to drill the holes and did not bother with tool changes. I then used

the table saw to cut my block of wood in half. You could also just run the program twice on 2 blocks of wood. Since the holes

and the mold halves are machined in 1 setup, the holes and hemispheres should line up nicely when you bolt it together for casting.

milling gcode file - cb-mold.ngc(3.9k)

Back to Lawrence's Software Stuff Page

Back to Lawrence's Software Stuff Page

Casting Lead Down-rigger Balls in a Wooden Mold

Casting Lead Down-rigger Balls in a Wooden Mold

Casting Lead Down-rigger Balls in a Wooden Mold

Casting Lead Down-rigger Balls in a Wooden Mold

![]()

![]()